How to Test Centralizer Starting Force and Running Force?

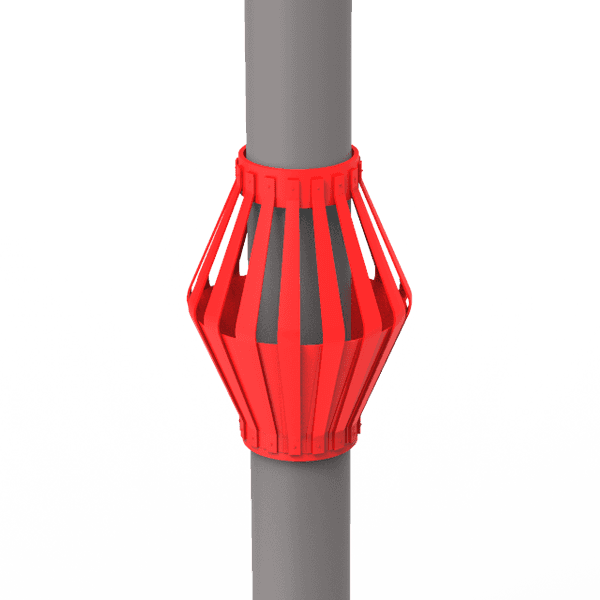

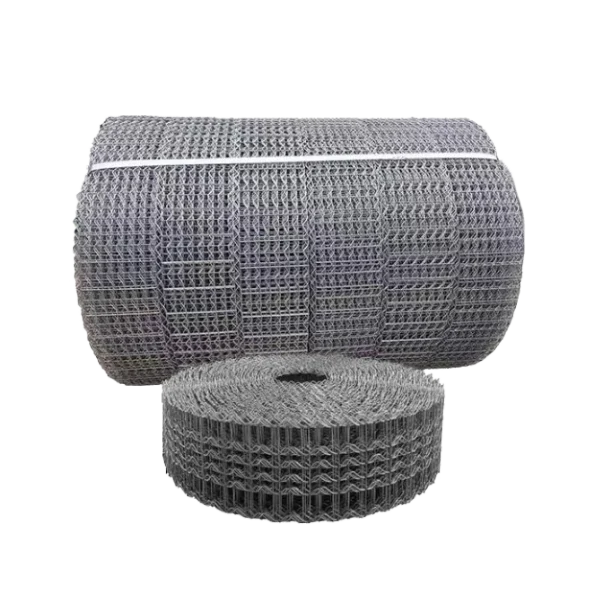

Bow spring centralizer is designed for primary cementing and applied in vertical, deviated and horizontal wells where low starting force and high restoring force are required.

Starting force and running force are key parameters that measure the quality of bow spring centralizers. Here, we'd like to briefly introduce what the starting force is, what the running force is, devices and samples required for starting force testing and running force testing, test procedures and results.

Starting force refers to the maximum force required to insert a centralizer into a specified wellbore diameter. Starting force values can vary depending on the installation methods. Running force refers to the maximum force required to move a centralizer through a specified wellbore diameter.

The maximum starting force shall be less than the weight of 12.19 m (40 ft) of medium linear mass as defined in Table 1. The maximum starting force shall be determined for a centralizer in new, fully assembled condition.

Table 1 Casing Centralizer Specification – Starting Force

| Casing Diameter |

Medium Linear Mass Casing |

Maximum Starting Force |

| mm |

inch |

kg/m |

lb/ft |

N |

lbf |

| 89 |

3-1/2" |

14.7 |

9.91 |

1761 |

396 |

| 102 |

4" |

16.9 |

11.34 |

2019 |

454 |

| 114 |

4-1/2" |

17.3 |

11.6 |

2064 |

464 |

| 127 |

5" |

19.3 |

13.0 |

2313 |

520 |

| 140 |

5-1/2" |

23.1 |

15.5 |

2758 |

620 |

| 168 |

6-5/8" |

35.7 |

24.0 |

4270 |

960 |

| 178 |

7" |

38.7 |

26.0 |

4626 |

1040 |

| 194 |

7-5/8" |

39.3 |

26.4 |

4697 |

1056 |

| 219 |

8-5/8" |

53.6 |

36.0 |

6405 |

1440 |

| 244 |

9-5/8" |

59.5 |

40.0 |

7117 |

1600 |

| 273 |

10-3/4" |

75.9 |

51.0 |

9074 |

2040 |

| 298 |

11-3/4" |

80.4 |

54.0 |

9608 |

2160 |

| 340 |

1-3/8" |

90.8 |

61.0 |

10854 |

2440 |

| 406 |

16" |

96.7 |

65.0 |

11565 |

2600 |

| 473 |

18-5/8" |

130.2 |

87.5 |

15569 |

3500 |

| 508 |

20" |

139.9 |

94.0 |

16725 |

3760 |

NOTE:

- The specifications for restoring force for bow spring centralizers are based on the centralizer being installed as per manufacturer recommendations and tested with lugs on the casing. If the centralizer is tested over a casing collar, stop collar, or with an integral stop collar, the actual results obtained from that test can vary from the specifications. It should be noted on the test report how the centralizer was installed and the type of holding device used during the test. If a centralizer is tested in this manner, the test can no longer be considered a specification test and the results may or may not meet the specifications set forth in Table 1

- Casing diameter refers to the liner sizes.

- Medium linear mass casing refers to the plain-end weight.

|

Samples & Test Stand Preparation

- Samples

Get at least 6 prototype centralizers well prepared for design and process verification testing. All centralizers used shall conform to the performance requirements of Table 1.

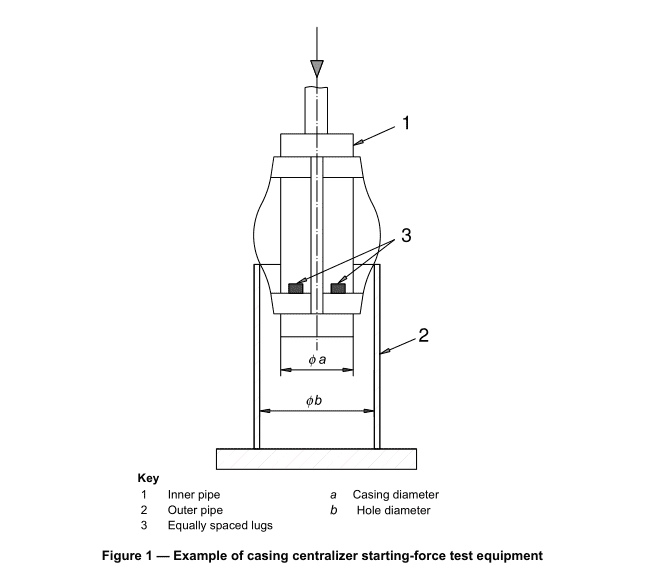

- Test stand The test stand allows the application of vertical loads and is capable of measuring these loads and vertical displacements.

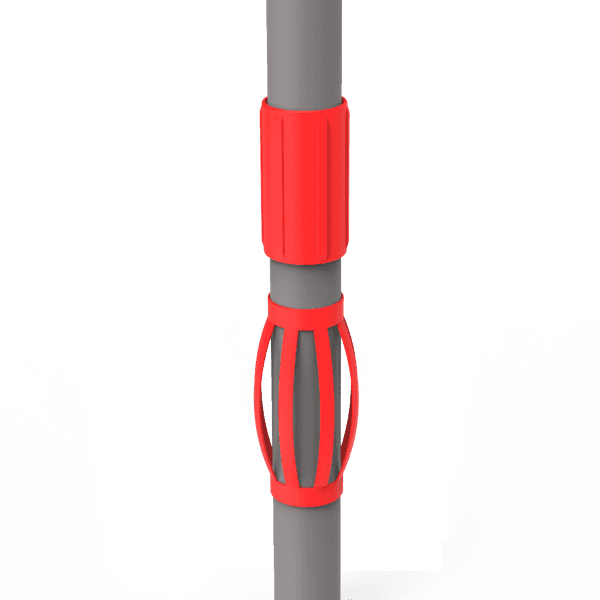

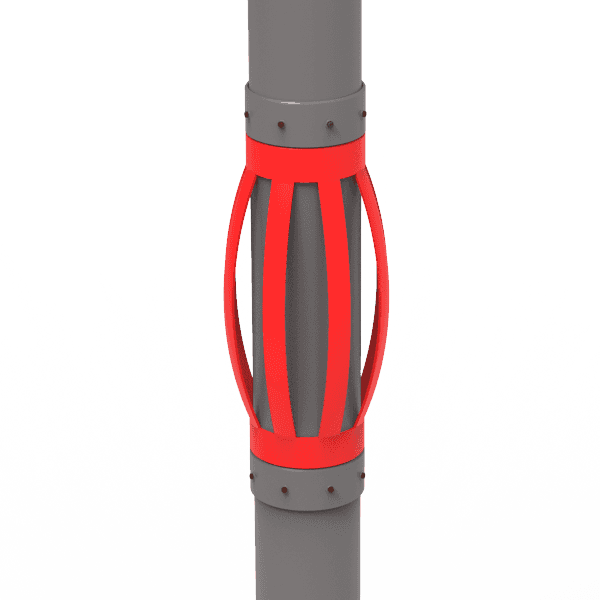

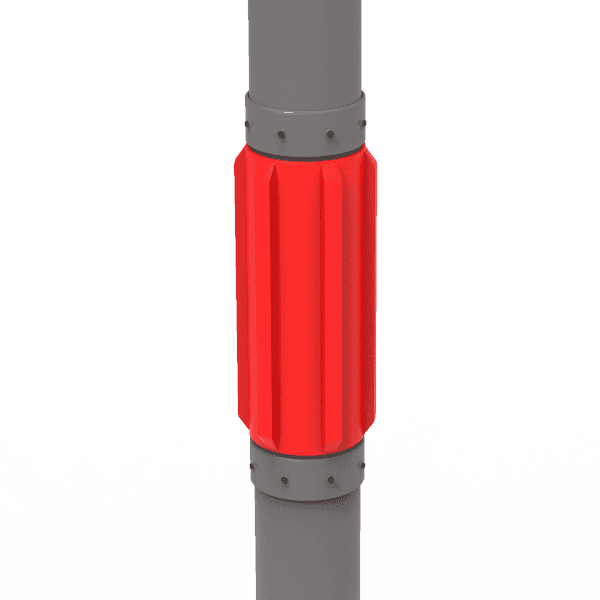

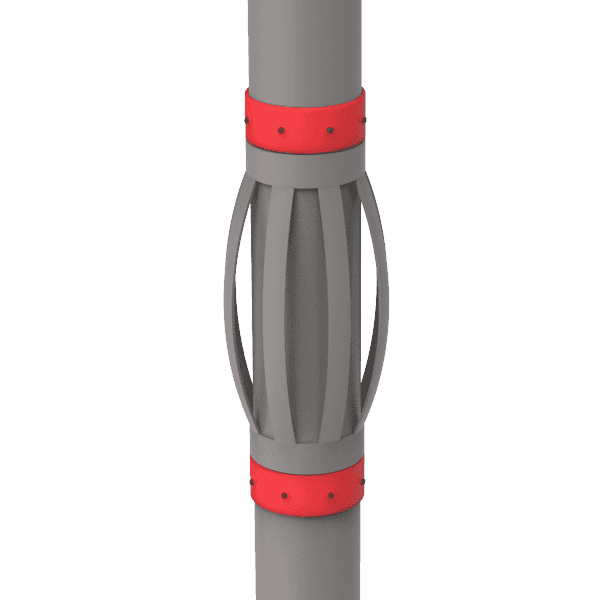

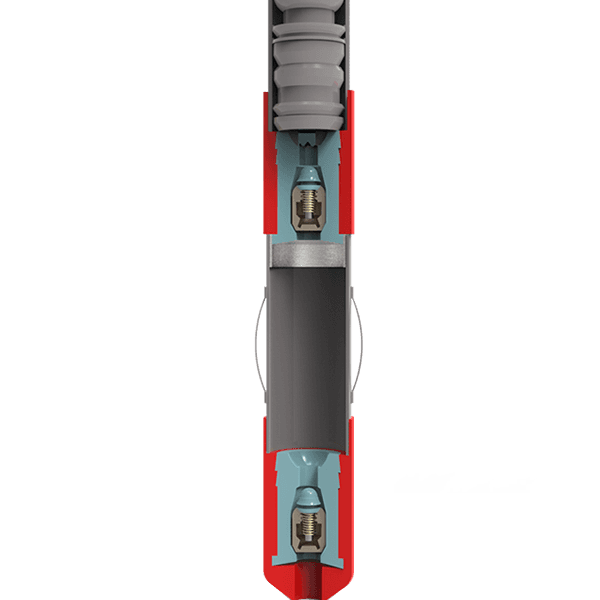

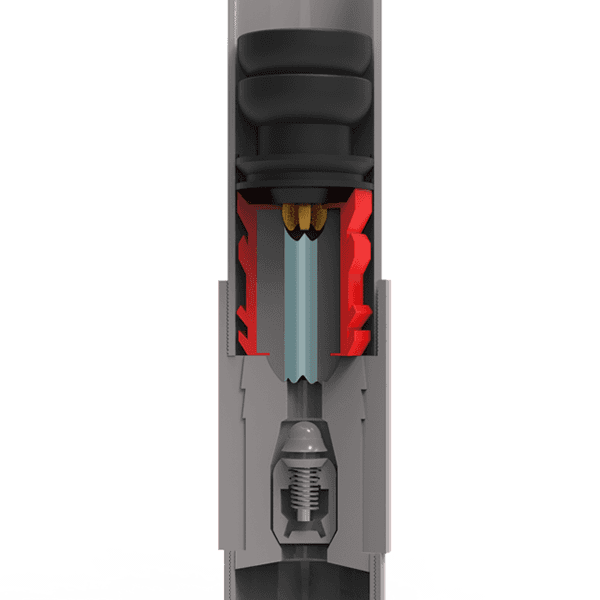

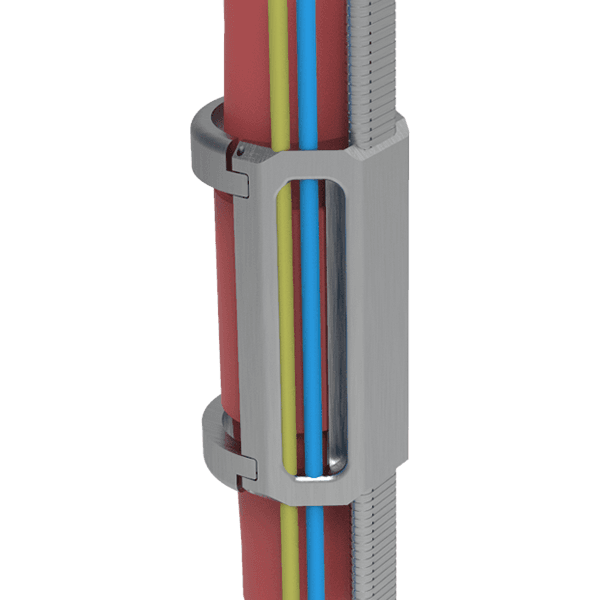

Example of casing centralizer starting force test equipment

Casing centralizer starting force test

- Instrumentation

Instrumentation of the test stand shall allow displacement readings of 1.6 mm (1/16") or smaller.

- Accuracy

- Accuracy of load measurements shall be within 5% of the measured value.

- Accuracy of displacement measurements shall be within 0.8 mm (1/32").

- All measuring devices shall be calibrated at least annually.

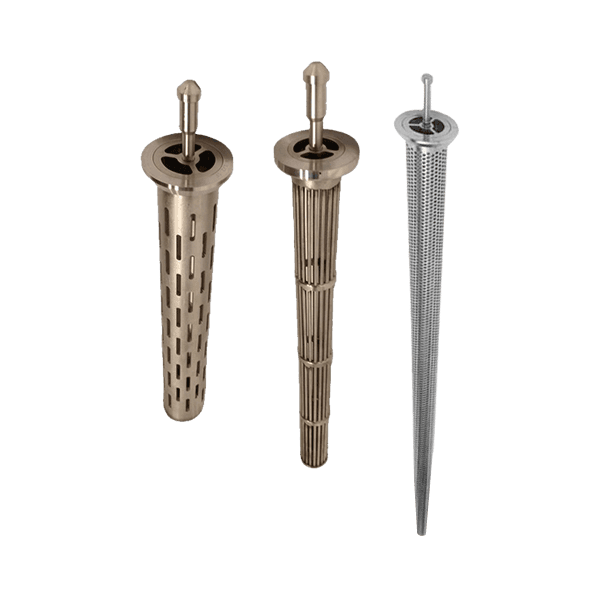

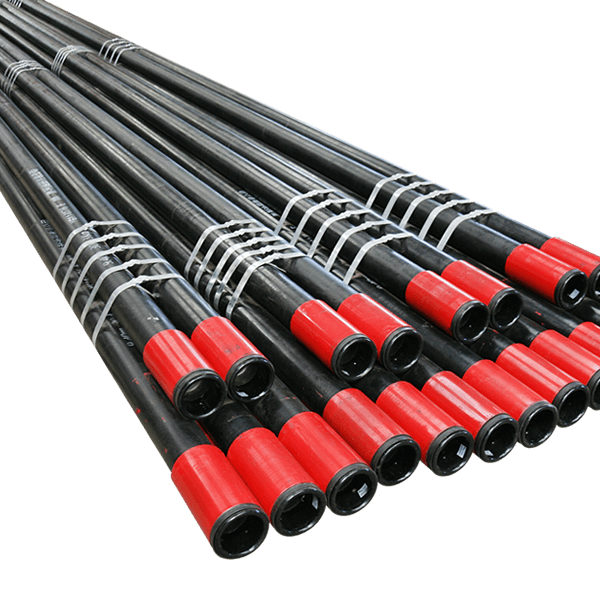

- Test Pipe

- Inner pipe

The inner pipe (Figure 1) shall be longer than the centralizer in the flexed condition and longer than the outer pipe. The outside diameter of the inner tube shall be within the tolerances shown in ISO 11960 for non-upset pipe. Burrs or similar defects shall be removed.

Surfaces on the ends of the inner pipe, outside the length to be covered by the centralizer and other test components, are exempt from the above requirements.

- Outer pipe

The outer pipe (Figure 1) shall be longer than the centralizer bow spring in the flexed condition. The inside diameter of the outer pipe shall be equal to the hole size for which the centralizer is designed. Tolerance shall fall within -0.8 mm to +3.2 mm (-1/31" to +1/8"). Burrs or similar defects shall be removed.

The end of the outer pipe (other than the upper end used for starting force tests), beyond the length covered by the centralizer when flexed during the restoring force test, is exempt from the above requirements.

Starting Force Test Procedures

- The starting force represents the maximum force required to insert the inner pipe into the outer pipe (after compensating for the weight of the inner pipe and attachments.) It is determined as described in starting force test procedure 2 to 6.

- Install a centralizer in new, fully assembled condition as shown in Figure 1 on the inner pipe over four equally spaced lugs, with each lug protruding not more than 6.4 mm (1/4") beyond the outer surface of the inner pipe.

Note: Under field conditions, there are many different methods of attaching a centralizer to the casing. The starting and restoring forces for all types of holding devices may not be the same as the test results obtained using this procedure.

- The test assembly shall be within 5° of vertical.

- Lubricate the contacting surfaces with a petroleum-base grease before running the test.

- With the centralizer testing on the edge of the outer pipe, apply a load to the inner pipe to pull the centralizer into the outer pipe.

- Take readings of force used, from the time the load is first applied until the centralizer is completely inside the outer pipe. Report the maximum force as the starting force after compensation as in starting force test procedure 1.

Running Force Test Procedures

- The running force represents the maximum force required to slide the inner pipe inside the outer pipe once the force reading has become steady (after compensating for the weight of the inner pipe and attachments).

- The result of this test is not required to conform to a maximum value. However, the test shall be performed and the results recorded.

- The running force test may be performed with the starting force test, or carried out separately.

- Taking readings of force used from the time the centralizer is inside the outer pipe until the inner pipe is completely in place. Report the maximum force as the running force after compensation as in running force test procedure 1.