- Home

-

Products

-

API Thread Protector

-

Mud Pump Accessories

-

BOP Rubber Accessories

-

Downhole Tool Rubber Components

-

Casing Centralizers

-

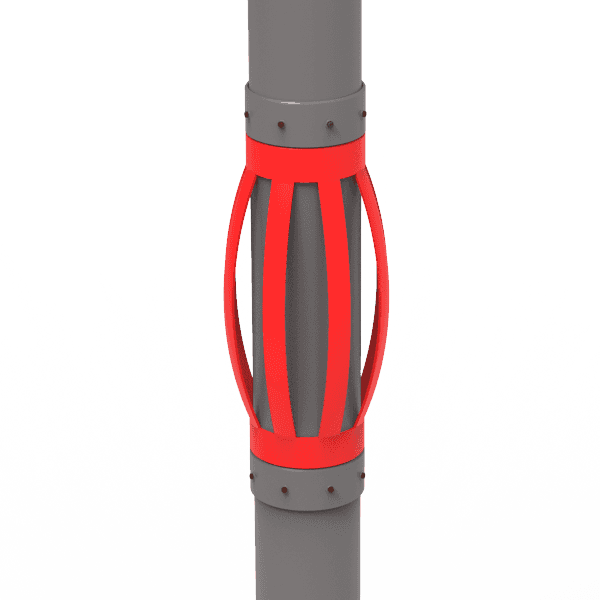

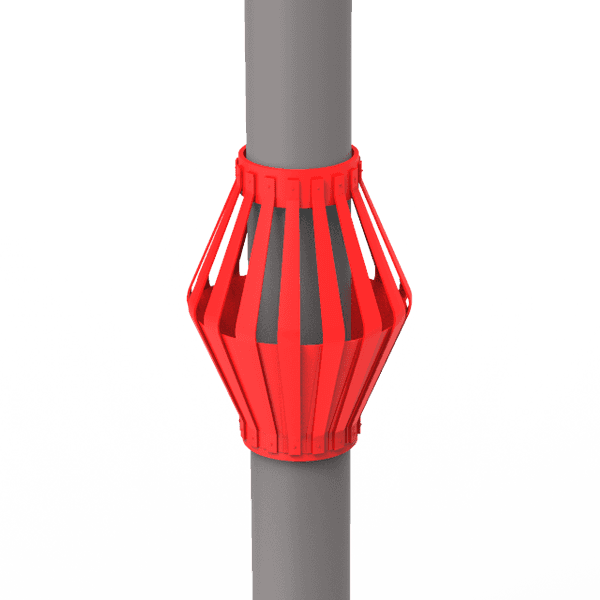

Bow Spring Centralizers

-

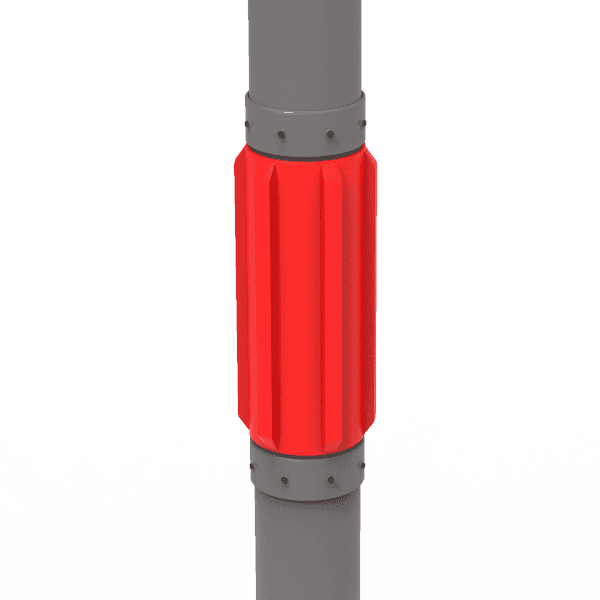

Solid Rigid Centralizer

-

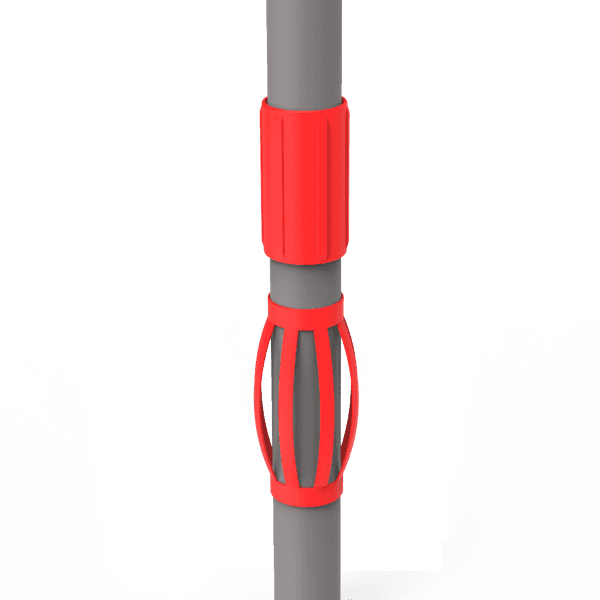

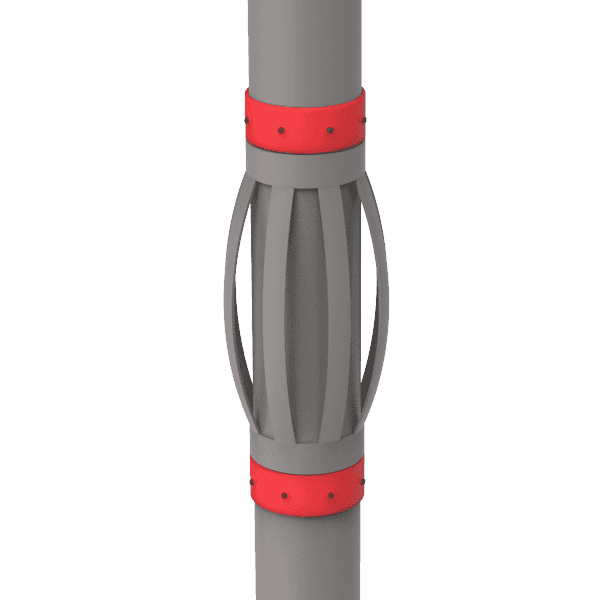

Stop Collar

-

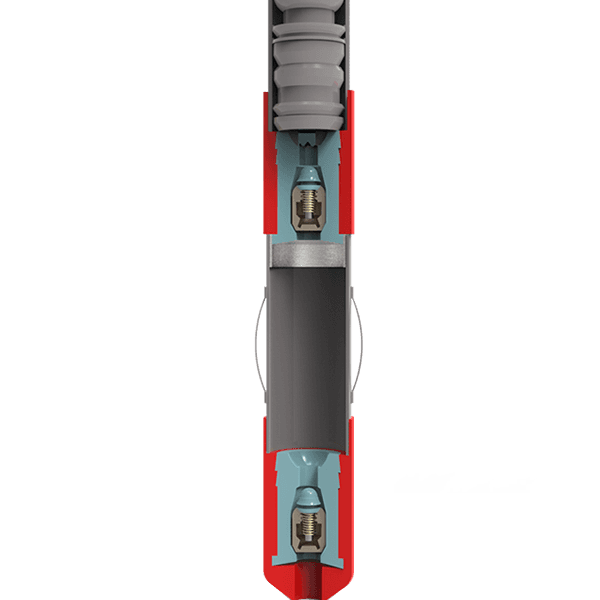

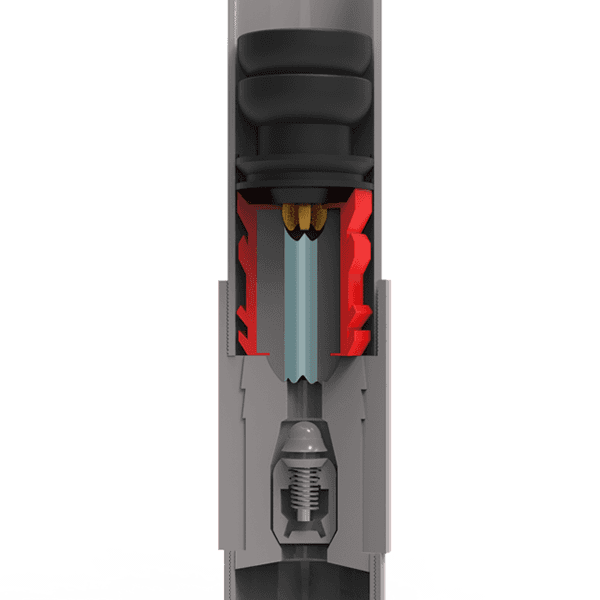

Cement Float Shoe & Collar

-

Cementing Plug

-

Cementing Baskets

-

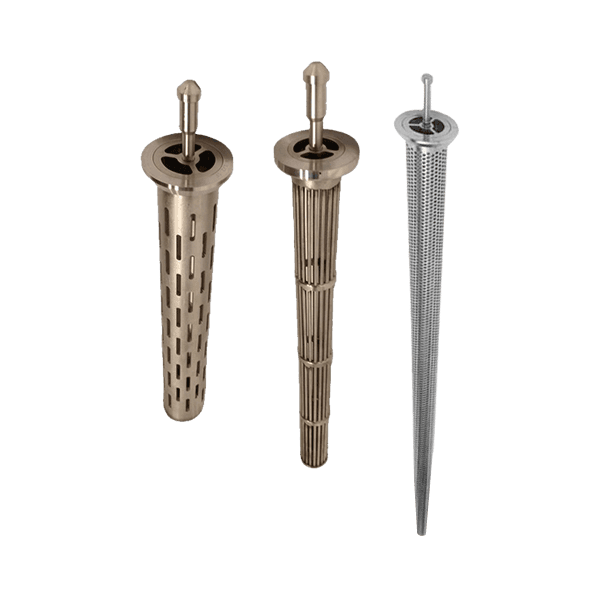

Drill Pipe Screen

-

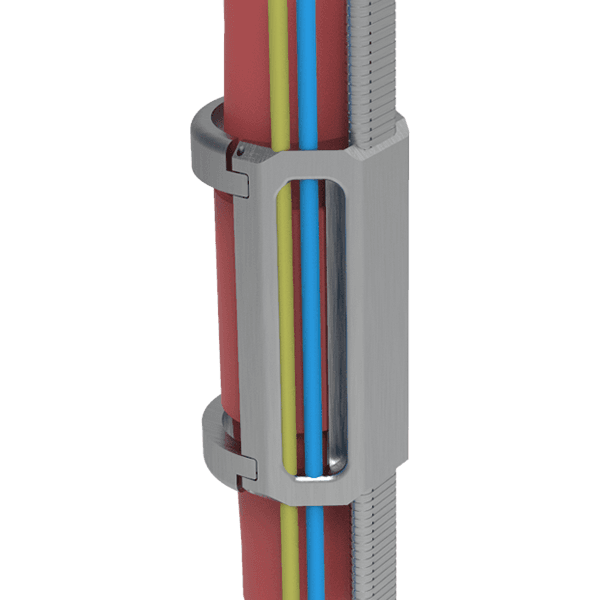

ESP Cable Protector

-

Sucker Rod Centralizer

-

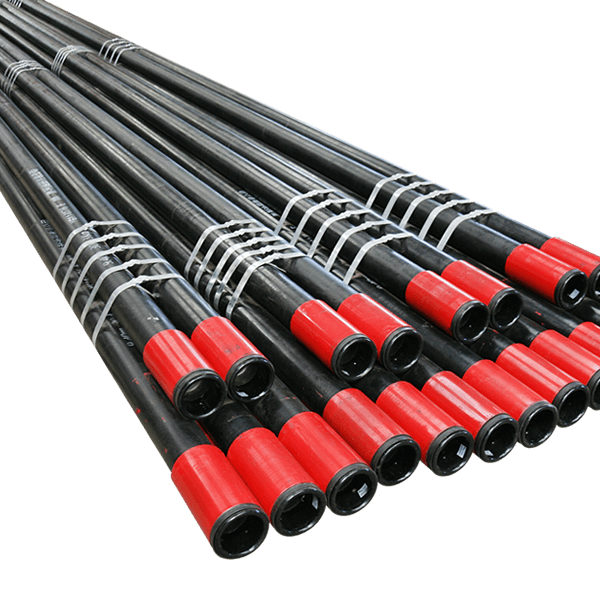

API Casing Pipe

-

Pipe Packaging Frames

-

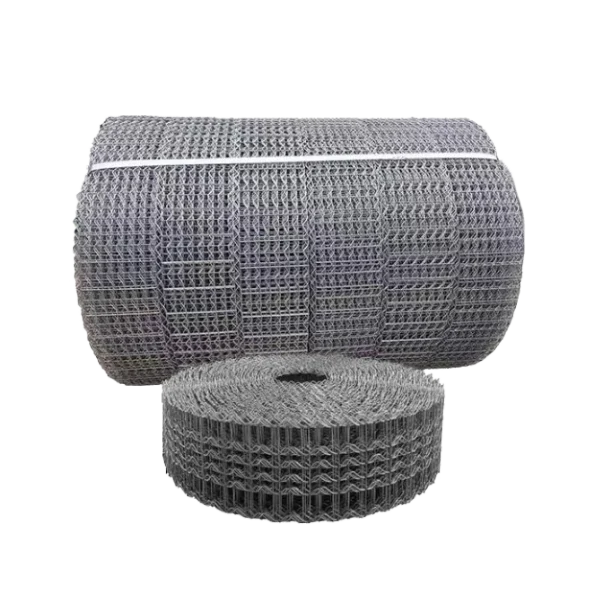

Concrete Weight Coating Mesh (CWC Mesh))

-

Wedge Wire Screen

-

Drilling Fluid Purification Systems

-

Drilling Fluid Purification Auxiliary Equipment

-

- Service

- Manufacturing

- About Us

- Contact

- Home

-

Products

- API Thread Protector

- Mud Pump Accessories

- BOP Rubber Accessories

- Downhole Tool Rubber Components

- Casing Centralizers

- Bow Spring Centralizers

- Solid Rigid Centralizer

- Stop Collar

- Cement Float Shoe & Collar

- Cementing Plug

- Cementing Baskets

- Drill Pipe Screen

- ESP Cable Protector

- Sucker Rod Centralizer

- API Casing Pipe

- Pipe Packaging Frames

- Concrete Weight Coating Mesh (CWC Mesh))

- Wedge Wire Screen

- Drilling Fluid Purification Systems

- Drilling Fluid Purification Auxiliary Equipment

- Service

- Manufacturing

- About Us

- Contact