- Hogar

-

Productos

-

Protector del hilo del API

-

Mud Pump Accessories

-

BOP Rubber Accessories

-

Downhole Tool Rubber Components

-

Centralizadores de la cubierta

-

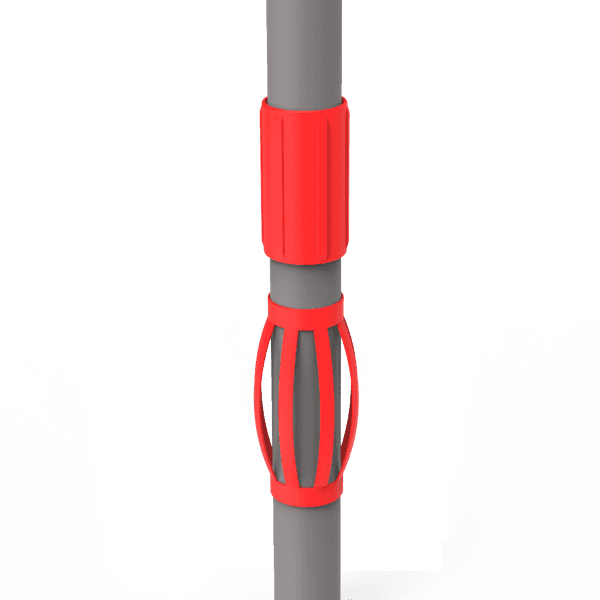

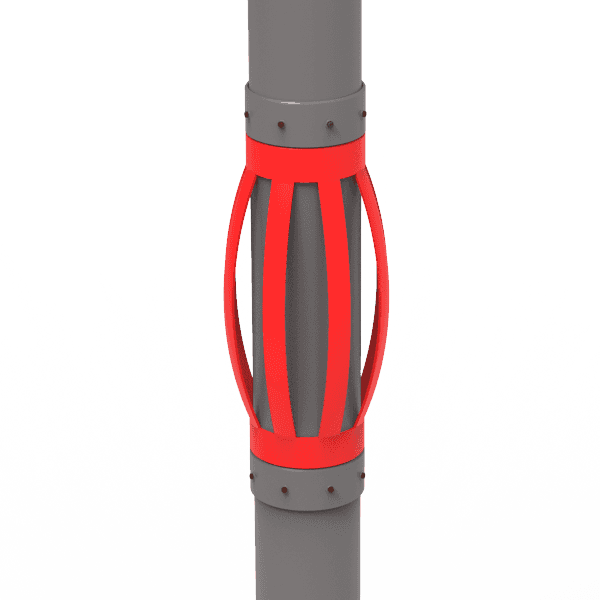

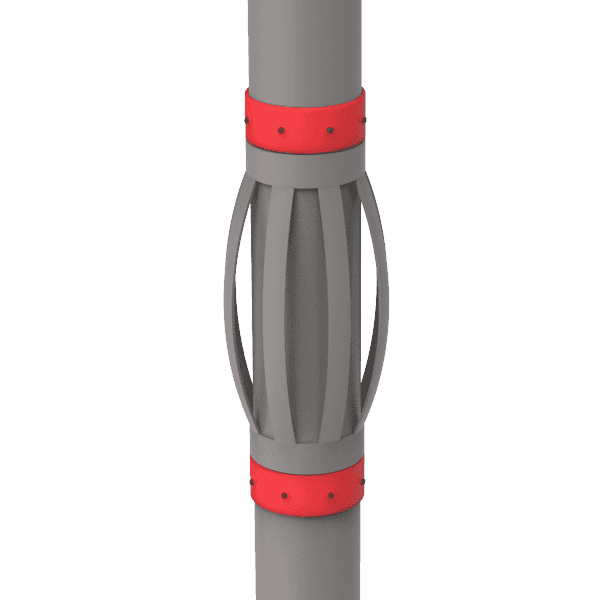

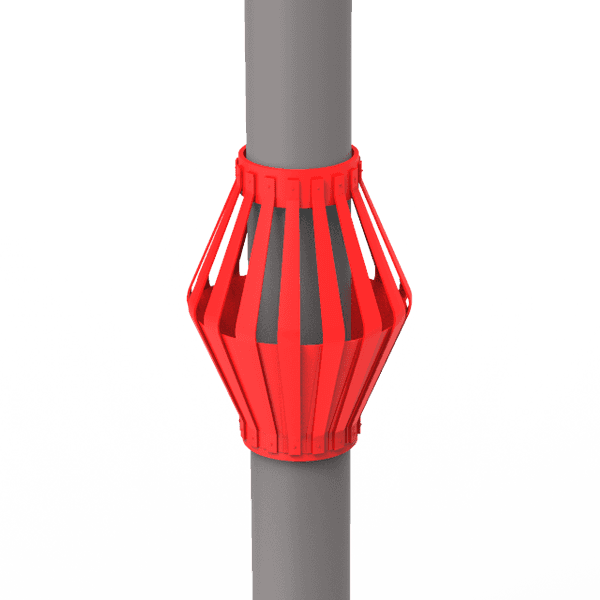

Bow Spring Centralistas

-

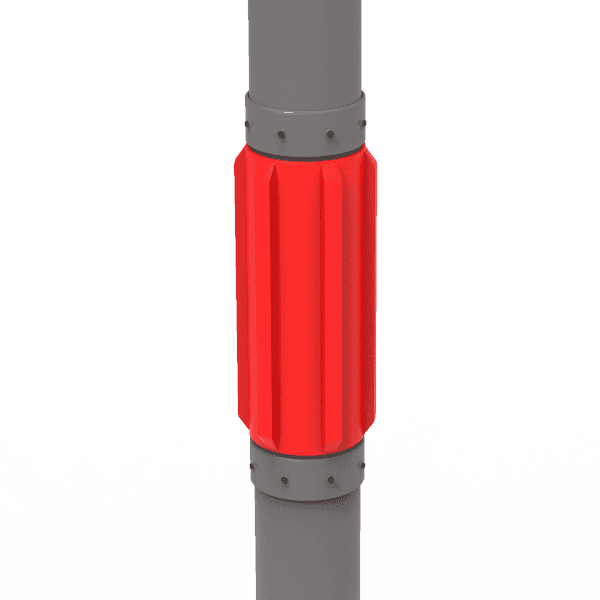

Centralizador Rígido

-

Collar de parada

-

Zapato y collar del cemento

-

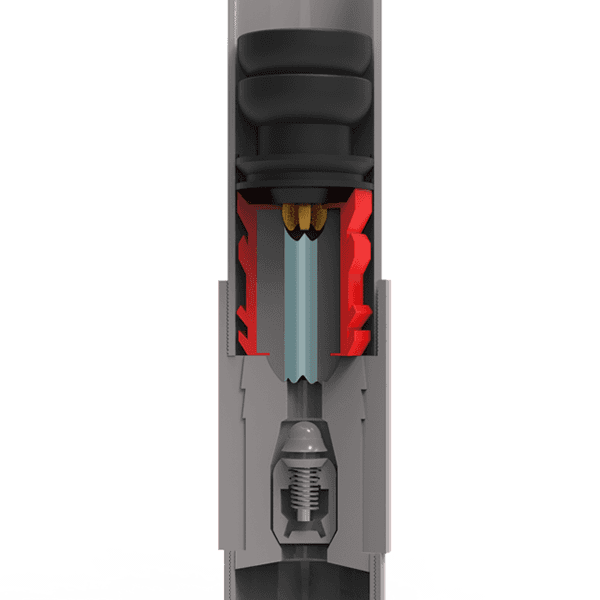

Enchufe de cementación

-

Cestas de cementación

-

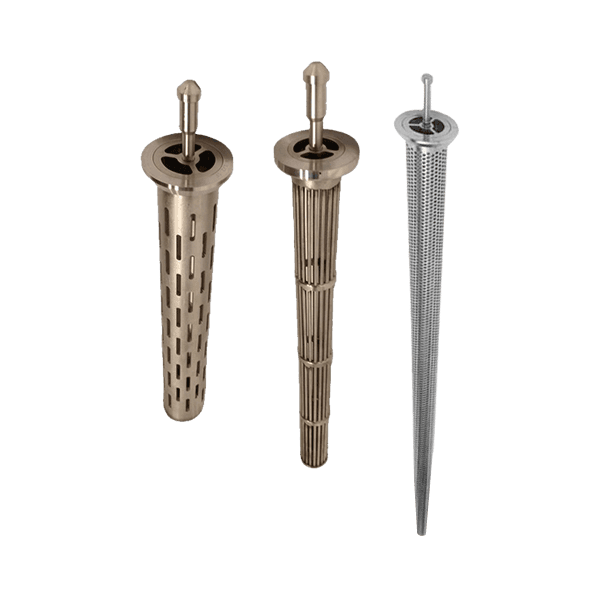

Pantalla del tubo de taladro

-

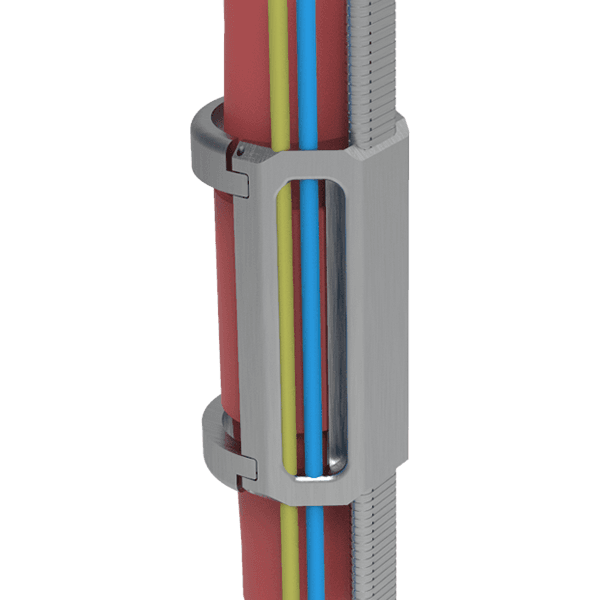

Protector del cable de ESP

-

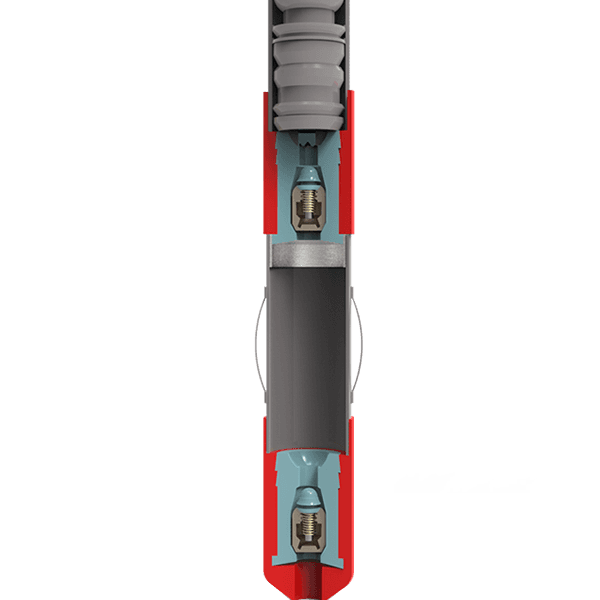

Sucker Rod Centralizador

-

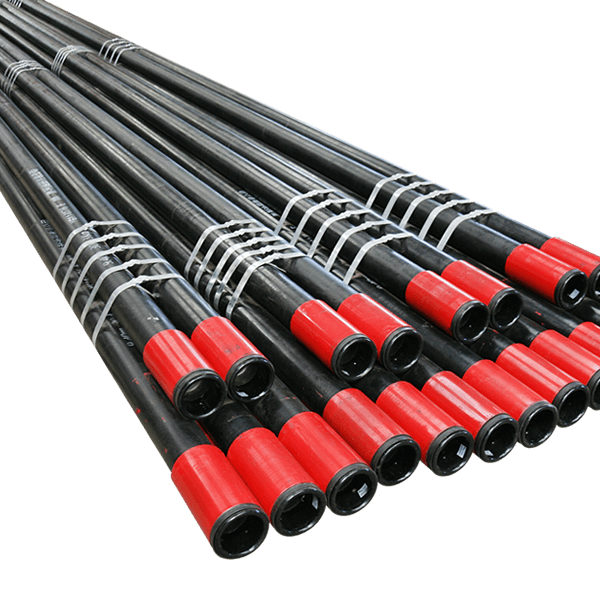

Tubería de carcasa API

-

Marcos de embalaje de tubería

-

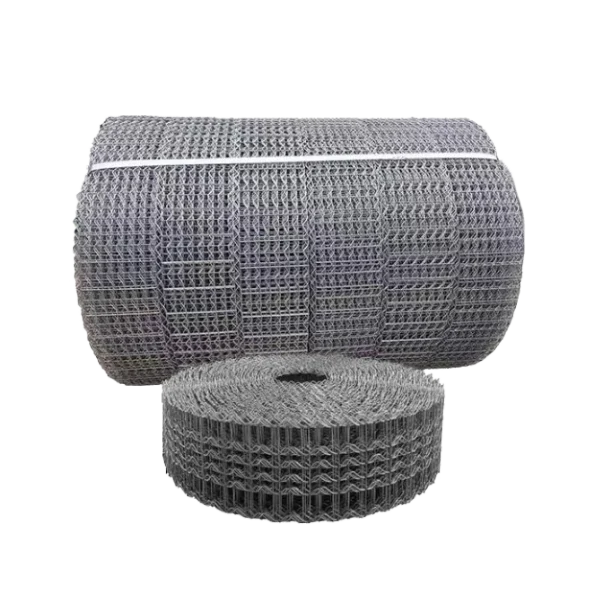

Malla de recuperación de peso de hormigón (malla CWC)

-

Pantalla de alambre de la cuña

-

Sistemas de purificación de fluidos de perforación

-

Equipo auxiliar de purificación de fluidos de perforación

-

- Servicio

- Fabricación

- Sobre nosotros

- Contacto

- Hogar

-

Productos

- Protector del hilo del API

- Mud Pump Accessories

- BOP Rubber Accessories

- Downhole Tool Rubber Components

- Centralizadores de la cubierta

- Bow Spring Centralistas

- Centralizador Rígido

- Collar de parada

- Zapato y collar del cemento

- Enchufe de cementación

- Cestas de cementación

- Pantalla del tubo de taladro

- Protector del cable de ESP

- Sucker Rod Centralizador

- Tubería de carcasa API

- Marcos de embalaje de tubería

- Malla de recuperación de peso de hormigón (malla CWC)

- Pantalla de alambre de la cuña

- Sistemas de purificación de fluidos de perforación

- Equipo auxiliar de purificación de fluidos de perforación

- Servicio

- Fabricación

- Sobre nosotros

- Contacto