- Главная

-

Продукция

-

Протектор резьбы API

-

Mud Pump Accessories

-

BOP Rubber Accessories

-

Downhole Tool Rubber Components

-

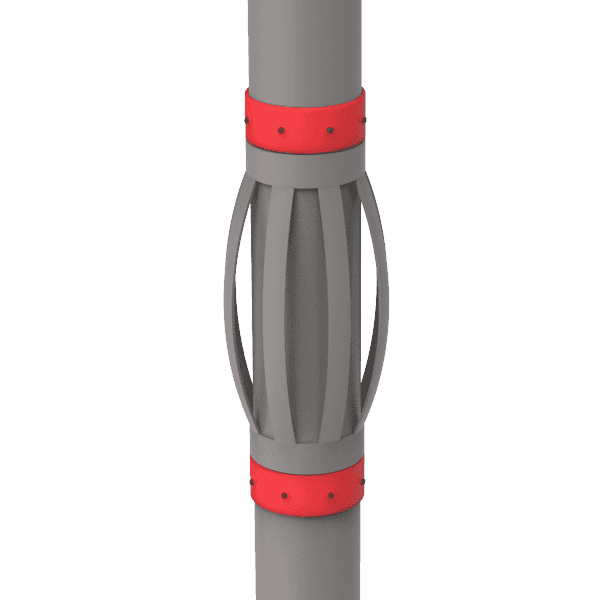

Корпус Централизаторы

-

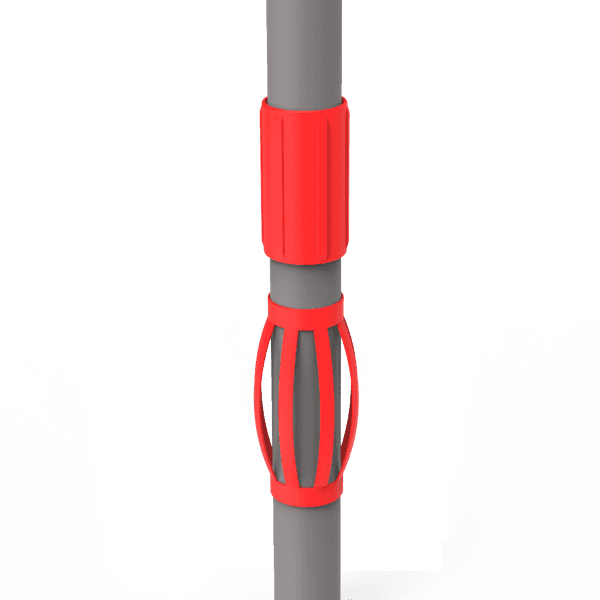

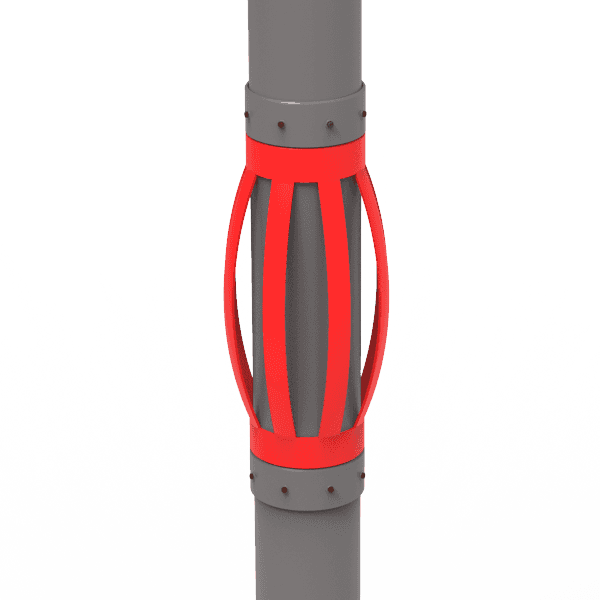

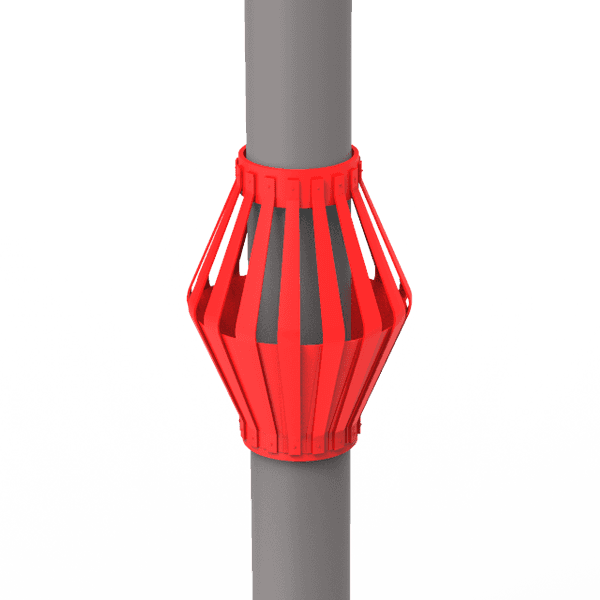

Лук Весна Центраторы

-

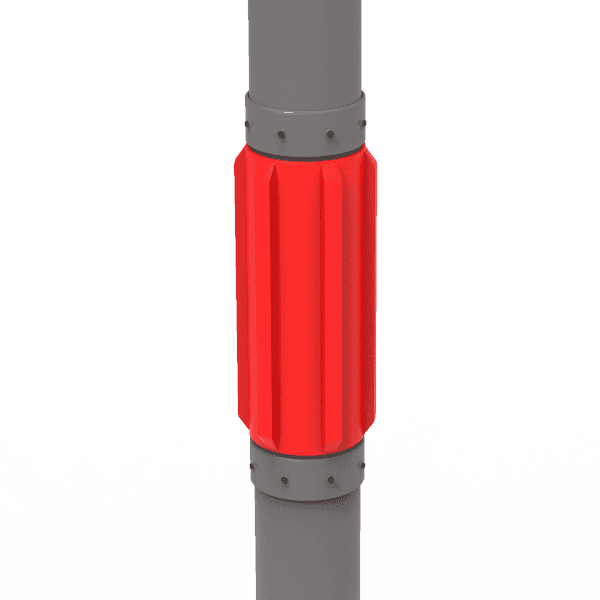

Твердый Жесткий Центр

-

Стоп Воронник

-

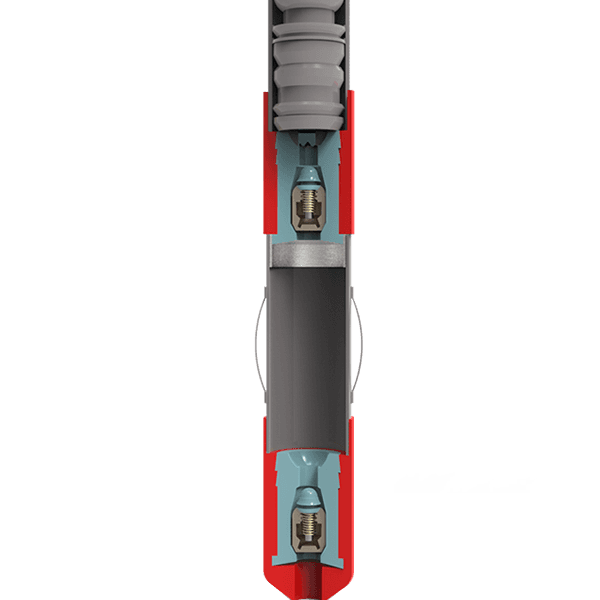

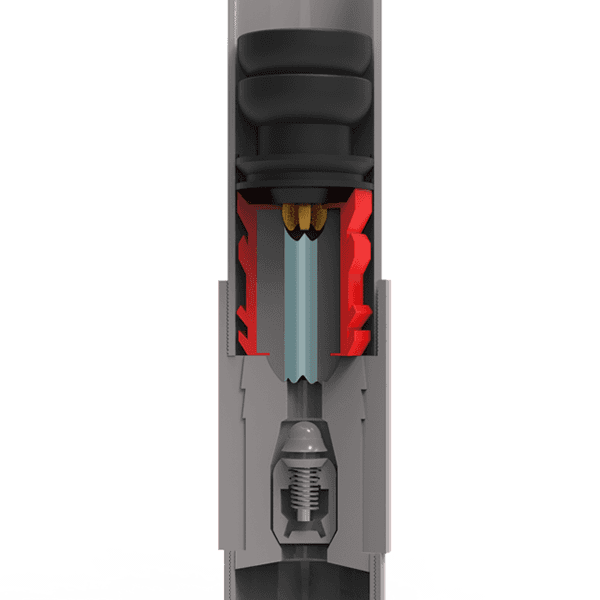

Цемент Поплавок Обувь & Воротник

-

Цементировная заглушка

-

Цементировочные корзины

-

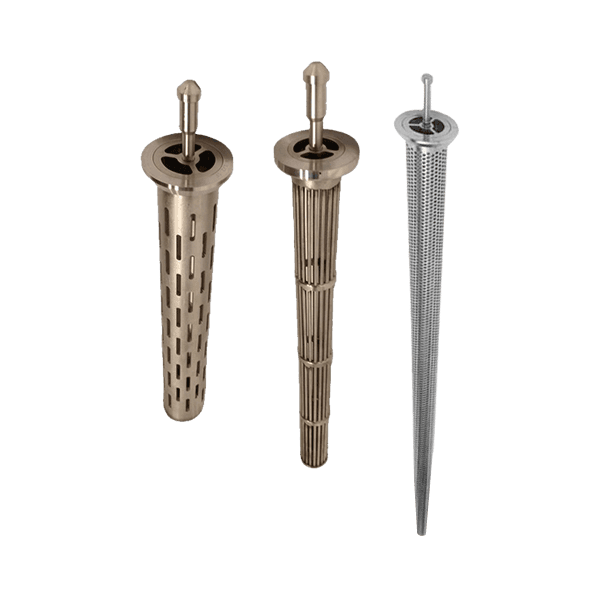

Экран бурильной трубы

-

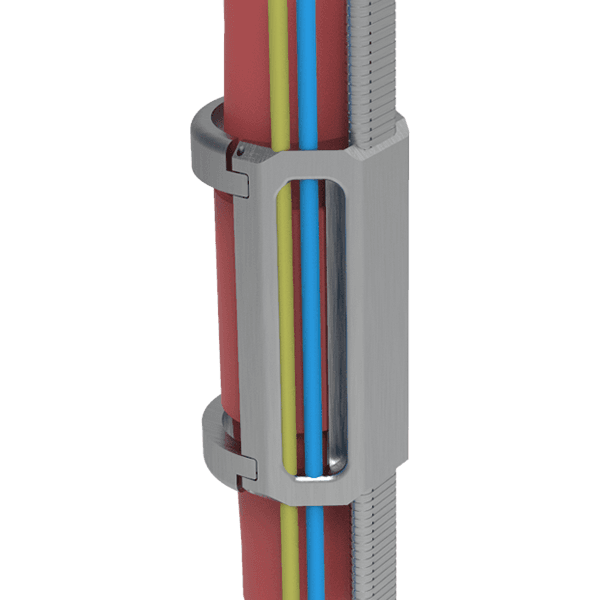

Протектор кабеля ЭСП

-

Централизатор Присоски СТЕРЖНЯ

-

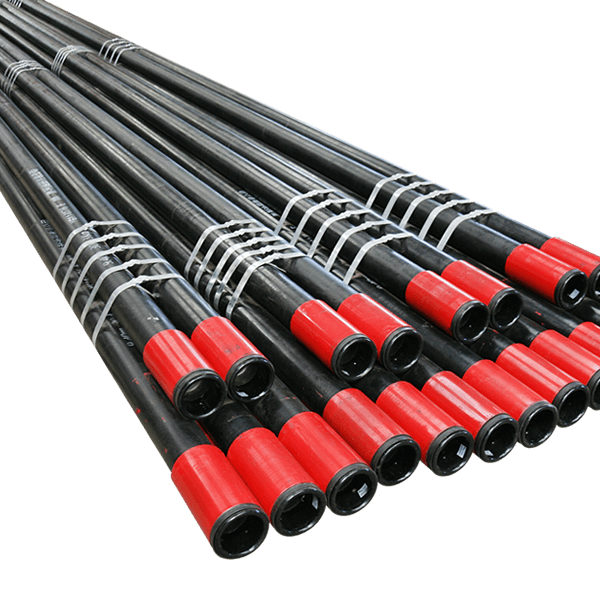

Труба обсадной трубы API

-

Рамки Упаковки Руб

-

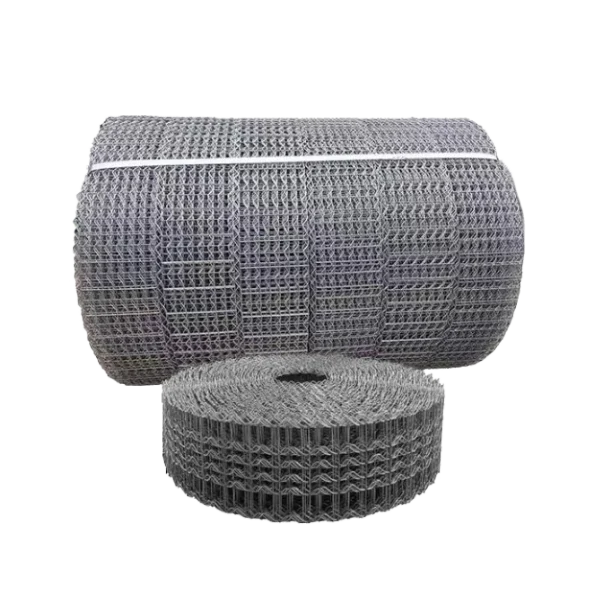

СЕТКА ПОКРЫТЯ БЕТОНного ВЕСа (СЕТКА CWC)

-

Экран провода клина

-

Системы очистки буровой жидкости

-

Вспомогательное оборудование для очистки буровой жидкости

-

- Сервис

- Производство

- О нас

- Контакт

- Главная

-

Продукция

- Протектор резьбы API

- Mud Pump Accessories

- BOP Rubber Accessories

- Downhole Tool Rubber Components

- Корпус Централизаторы

- Лук Весна Центраторы

- Твердый Жесткий Центр

- Стоп Воронник

- Цемент Поплавок Обувь & Воротник

- Цементировная заглушка

- Цементировочные корзины

- Экран бурильной трубы

- Протектор кабеля ЭСП

- Централизатор Присоски СТЕРЖНЯ

- Труба обсадной трубы API

- Рамки Упаковки Руб

- СЕТКА ПОКРЫТЯ БЕТОНного ВЕСа (СЕТКА CWC)

- Экран провода клина

- Системы очистки буровой жидкости

- Вспомогательное оборудование для очистки буровой жидкости

- Сервис

- Производство

- О нас

- Контакт